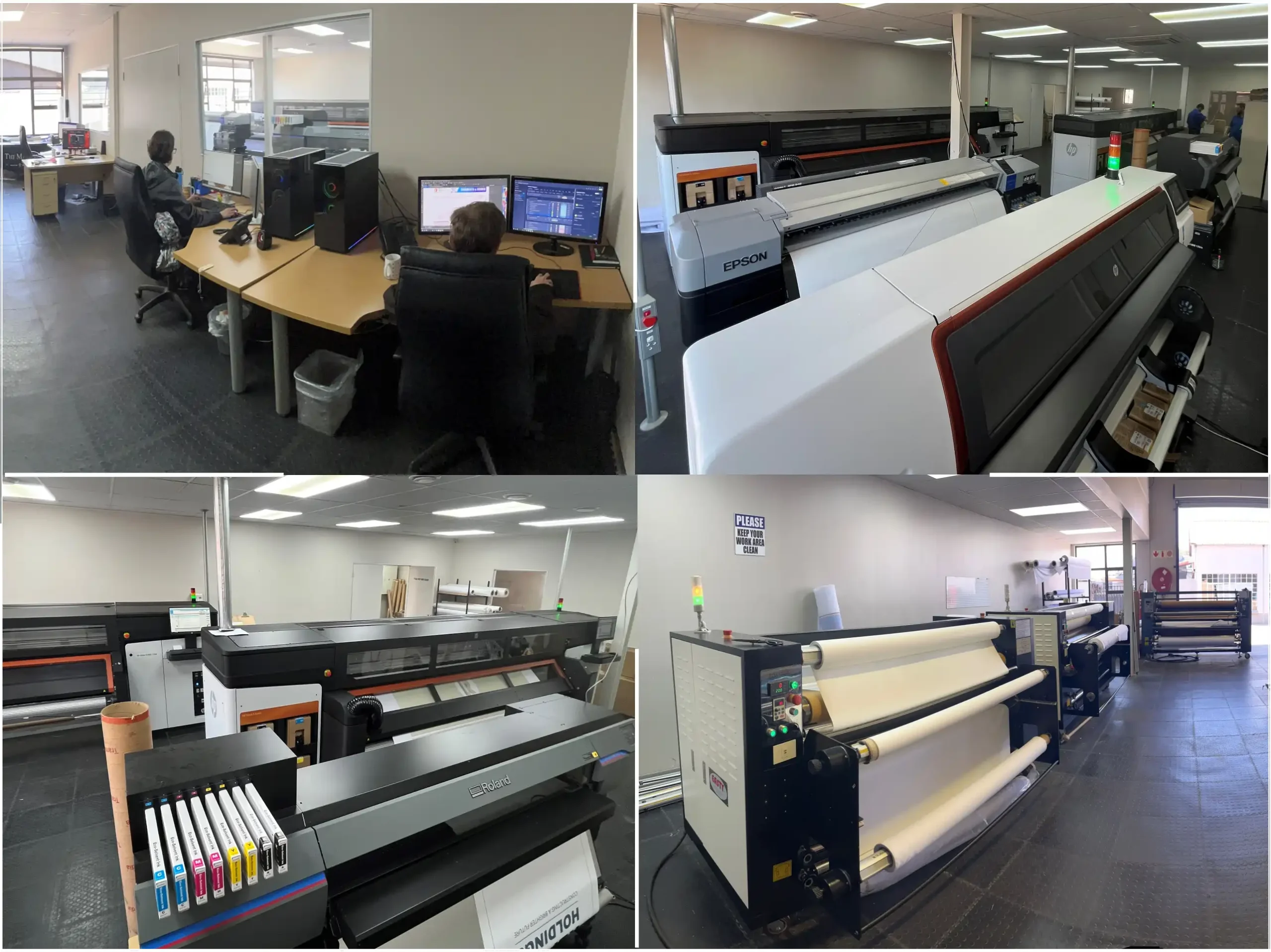

At Printagon Branding Solutions, we believe that great branding starts with great production.

That’s why we use professional-grade printing equipment and trusted techniques to ensure every product we deliver meets the highest standards for clarity, colour, and durability.

TRUST AND UNDERSTAND OUR PROCESS

What is Dye-Sublimation:

Dye sublimation is a premium digital printing process used to produce vibrant, long-lasting designs on polyester fabrics and coated materials. At Banner and Flag Online, we utilize two main methods of dye sublimation depending on the fabric type and product requirements—direct-to-fabric printing and transfer printing via sublimation paper. Both methods rely on a heat press to complete the process by bonding the ink permanently into the fabric fibers.

1. Direct-to-Fabric Dye Sublimation

This method involves printing specialized dye sublimation inks directly onto the fabric using high-resolution inkjet printers. After printing, the fabric is passed through a heat press, where high temperature and pressure are applied in a controlled process.

During this stage, the sublimation ink turns into gas and penetrates deep into the polyester fibers. As the fabric cools, the pores close and lock in the color, creating a print that is fully embedded in the material. This results in a soft, vibrant, and durable finish that won’t fade, crack, or peel over time.

2. Dye Sublimation Transfer (Paper to Fabric)

In this approach, the design is first printed onto special sublimation transfer paper. The printed paper is then placed face-down onto the blank fabric or item, and both are pressed together using a heat press.

At temperatures around 180–200°C, the inks on the paper vaporize and permeate the surface of the receiving material. Since the surface is polyester or polymer-coated, it opens at a molecular level to absorb the dye. Once cooled, the surface closes again, permanently bonding the color within the material.

This method is ideal for applications where direct-to-fabric printing is not suitable, but the same high-resolution, photorealistic results are required.

Why Choose Dye Sublimation:

No matter which method is used, dye sublimation offers:

- Deep, saturated colours

- Smooth gradients and fine detail

- Washable, fade-resistant prints

- A soft, professional finish

From banners and flags to soft signage and branded textiles, our dye sublimation process delivers superior quality that lasts.

Contact Us:

Head Office (Nationwide):

(010) 597 7754 | info@printagon.co.za

Cape Town (Western Cape):

(021) 203 1574 | infoct@printagon.co.za